Products

MyTWA AquaSolution Pvt. Ltd. operates as a joint venture, with Priyanjas OPV Pvt. Ltd. as one of its parent entities. Priyanjas OPV Pvt. Ltd. has already executed formal technology collaboration agreements for the following advanced solutions.

Supratec UF

Where extremely low turbidity and microbiological safety are required, membrane treatment is used as an additional technology along with TWA Catalyst

SUPRATEC UF is the ideal selection as it:

- Provides an ultrafiltration barrier to remove fine suspended solids, bacteria and many viruses.

- Combines biological treatment and solid–liquid separation in a single compact module.

- Operates at high flux with low specific energy consumption through optimized aeration.

- Uses automatic backwash and chemical cleaning to maintain stable performance with minimal operator effort.

Modular skid-mounted design, smaller footprint than conventional clarifier + filter trains, reduced chemical demand and sludge generation, and consistently clear permeate suitable for high-value reuse applications.

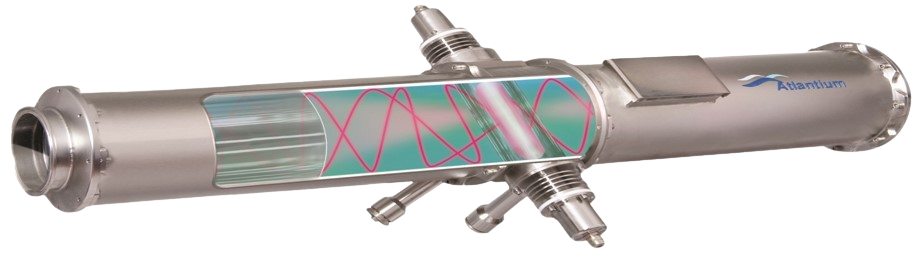

Atlantium UV

Where microbiological safety and chemical-free disinfection are required, UV treatment is used as an additional technology along with TWA Catalyst.

ATLANTIUM HODTM (Hydro-Optic Disinfection) UV is the ideal selection as it:

- Provides a physical, non-chemical disinfection process that exposes bacteria, viruses and protozoa to germicidal UV light so they cannot reproduce, with no residual chemicals left in the water.

- Uses medium-pressure, high-intensity UV lamps that emit a broad germicidal spectrum (≈200–415 nm), delivering high microbial inactivation with fewer lamps per system.

- Employs a quartz Hydro-Optic chamber with Total Internal Reflection (TIR) that recycles UV light, gives a homogeneous UV dose and improves power efficiency versus conventional UV systems.

- Continuously monitors UVT, flow and lamp intensity, auto-adjusting UV dose in real time and logging data to ensure the required disinfection level is always met.

Small-footprint inline system with a quartz disinfection chamber and extra-thick sleeves, reduced lamp-related maintenance, quick lamp replacement and advanced real-time monitoring / reporting, providing a reliable, validated UV barrier for critical water applications.

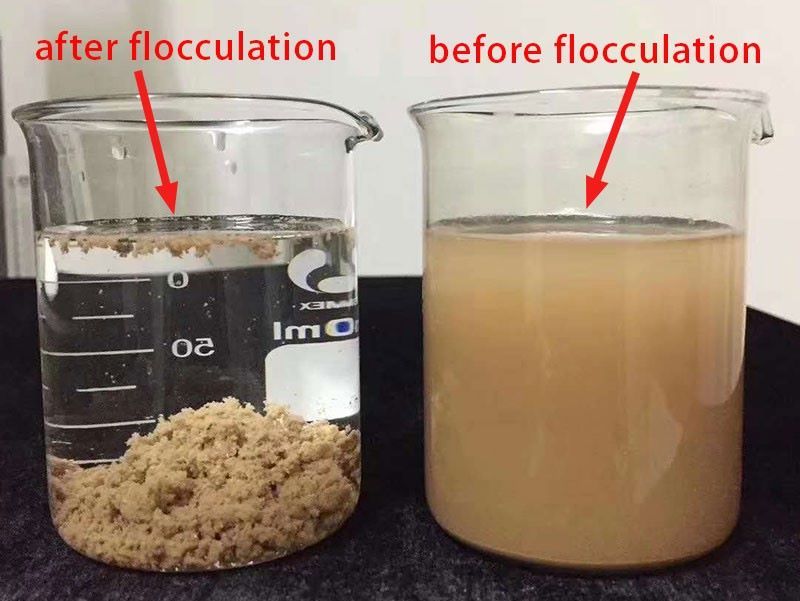

NSF 60 Bio-Flocculation

While the treated water with neutral colloids are still existing in the water to be treated post catalyst interaction, this needs to be removed with maximum clarification efficiency

NSF 60 Certified Zeo Turbo Bio-Flocculant is the ideal Selection as this flocculates all the colloids including neutralized colloids in four different ways.

- Charged Neutralization

- Sweep Coagulation

- Bridging

- Patch Flocculation

Derived from Deep Sea plants, Creates No Bi-Products and safe for even drinking

Water. Generates sludge that is only created to polluting analytes. No extra

sludge. Sludge concentration 1/10th that of generated by other Biological systems

Or synthetic Poly . Generated sludge is also safe for disposal under TCLP Protocol.

Gen Clean Disinfectant – Sea Water Pre-Treatment Process

- NSF-certified advanced oxidation technology designed for commercial, industrial, and municipal water treatment.

- ~4× stronger oxidizer than chlorine and ozone; stable for 6 months without loss of oxidation strength.

- Reduction efficiency depends on recirculating reaction time and dosage concentration.

Disinfection and oxidation effectiveness strongly correlates with ORP range. - Targets wide contaminants:

- Color, BOD, COD, trace organics/metals

- Microbiological contaminants: IRBs, SRBs, Legionella, viruses, algae, fungi, cysts (3–6 log reduction)

- Hydrogen sulfide (H₂S)

- Typical dosing requirements:

- Inorganics: <1 mg/L per mg/L of inorganic compound

- Microbial pathogens: 1 mg/L per 1,050–10,000 mg/L of pathogen

- Organics: 1–8 mg/L per mg/L of organic compound

- BOD/COD: 1 mg/L per 5–14 mg/L of COD

- H₂S, Mn, Fe: 1 mg/L per 2 mg/L of H₂S